VTHLON ARMOUR Fire Vehicle Superstructure

VTHLON ARMOUR

HIGHLIGHTS AND FEATURES

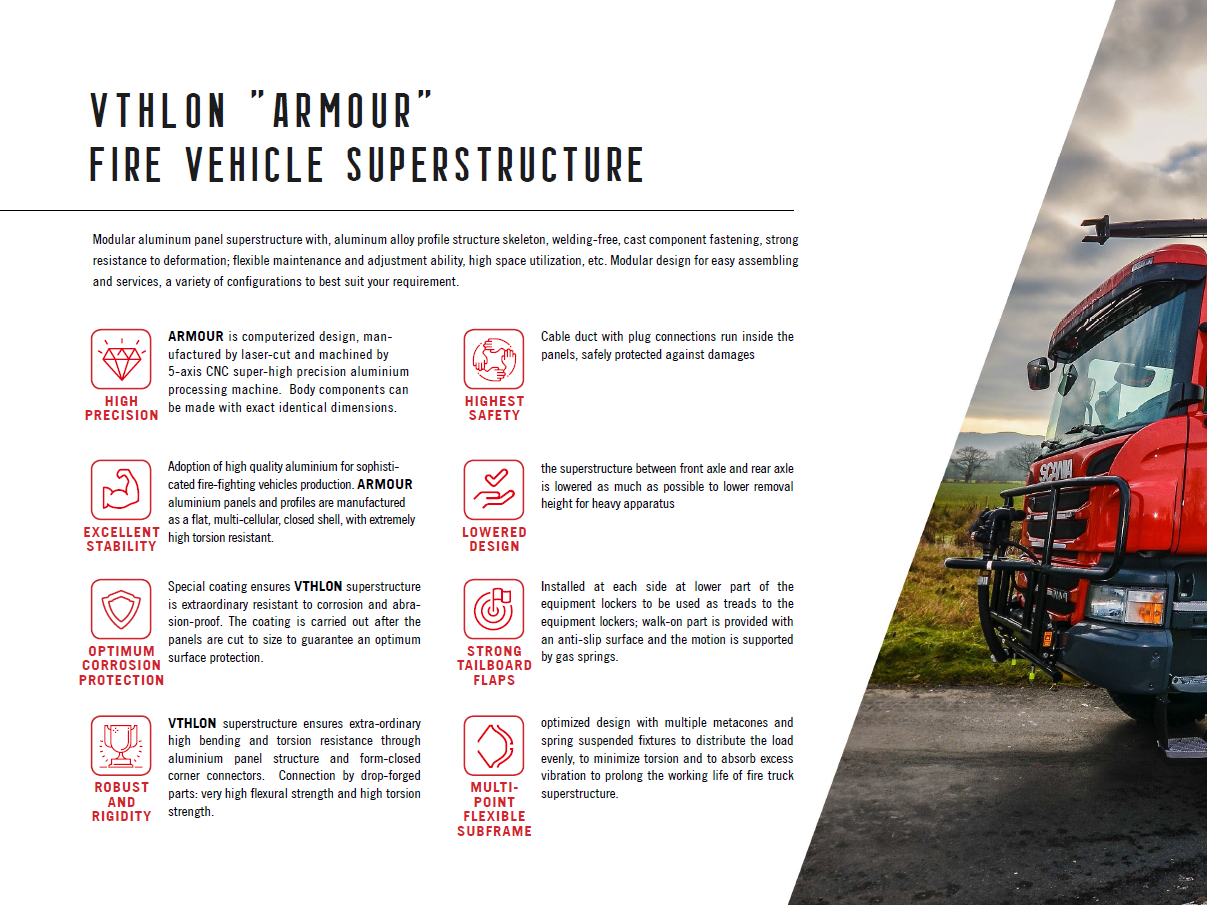

Modular aluminum panel superstructure with, aluminum alloy profile structure skeleton, welding-free, cast component fastening, strong resistance to deformation; flexible maintenance and adjustment ability, high space utilization, etc. Modular design for easy assembling and services, a variety of configurations to best suit your requirement.

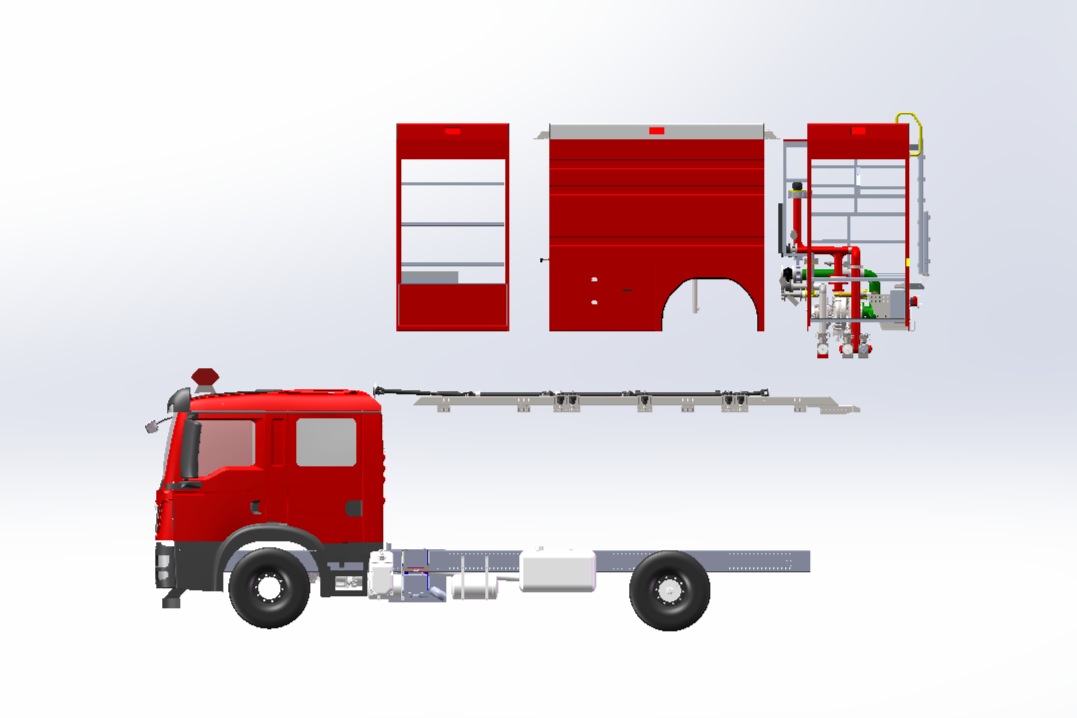

MODULAR DESIGN: ARMOUR Superstructure can be built in module, SKD or CKD which allows our distributors to mount on your local truck chassis easily.

WELD-FREE TECHNOLOGY: No special tools, low cost and easy to assemble, minimIzed deformation to ensure flat and straight edges and to prevent heat weaken the strength of material while welding.

HIGH PRECISION: ARMOUR is computerized design, manufactured by laser-cut and machined by 5-axis CNC super-high precision aluminium processing machine. Body components can be made with exact identical dimensions.

EXCELLENT STABILITY: Adoption of high quality aluminium for sophisticated fire-fighting vehicles production. ARMOUR aluminium panels and profiles are manufactured as a flat, multi-cellular, closed shell, with extremely high torsion resistant.

OPTIMUM CORROSION PROTECTION: Special coating ensures VTHLON superstructure is extraordinary resistant to corrosion and abrasion-proof. The coating is carried out after the panels are cut to size to guarantee an optimum surface protection.

ROBUST AND RIGIDITY: VTHLON superstructure ensures extra-ordinary high bending and torsion resistance through aluminium panel structure and form-closed corner connectors. Connection by drop-forged parts: very high flexural strength and high torsion strength.

HIGHEST SAFETY: Cable duct with plug connections run inside the panels, safely protected against damages

LOWERED DESIGN: the superstructure between front axle and rear axle is lowered as much as possible to lower removal height for heavy apparatus

STRONG TAILBOARD FLAPS: Installed at each side at lower part of the equipment lockers to be used as treads to the equipment lockers; walk-on part is provided with an anti-slip surface and the motion is supported by gas springs.